InterTwig

InterTwig is an experimental structure that combines willow, a fast regrowing material, and earth to showcase the potential of new sustainable construction methods based on digital construction technologies. Emerging from a materiality perspective, the project revisited historic building techniques that used natural materials, exemplified by the vernacular wattle and daub, to understand how these can be enhanced and rendered viable within the context of the fourth industrial revolution.

The structure has been developed by an interdisciplinary team of students and researchers from the Karlsruhe Institute of Technology (KIT) in Germany and results from the collaboration between the two chairs Digital Design and Fabrication (DDF) and Design of Structures (dos) at the Department of Architecture. InterTwig was exhibited at the Das Fest festival in July 2022 and will later travel to the Netherlands for the Dutch Design Week in October 2022.

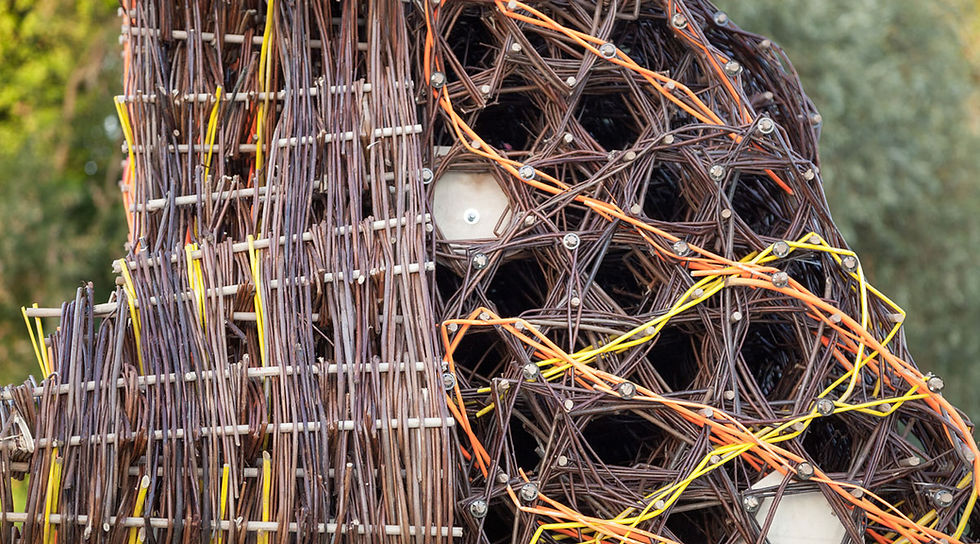

The design consists of 21 prefabricated components that can be quickly assembled and disassembled. Three-quarters of the components combine willow with earth and are geometrically interlocked and stacked to create a structurally stable base for the structure. On top, five components are arranged in different layer directionalities to create a vertical segment, which relies on integrated joints. Made primarily of willow, these showcase the intricate filigree of the material system.

Each component is formed by arranging regionally-sourced willow within a bed of wood poles in an additive process. A variety of geometric patterns and spatial arrangements of the willow branches allow the otherwise thin and bendable material to be configured into load bearing configurations which are locally further enhanced though the natural composite of earth, natural fibre and willow. Here, the willow acts as a permanent formwork and as a tension reinforcement.

Digital design methods enabled the exploration of different geometrical variations, together with the material research, and ensured an increased degree of control over the complexity at the different scales. At the same time, they afford the versatility and adaptability required by the different conditions. The structure was developed through traditional craftsmanship with the help of students at the Karlsruhe Institute of Technology, and the knowledge gained in the process was transferred into a customised digital fabrication process.

This research line is planned to advance further with new full-scale prototypes for the Bundesgartenschau in Mannheim in 2023

InterTwig within Circular Construction

As the building sector is responsible for more than a third of the global resource consumption, a shift towards circular construction cycles represents a major opportunity for the construction industry to curtail the depletion of raw materials. InterTwig represents the first step in a research line at KIT that aims to develop circular construction concepts enabled by digital design and fabrication and to explore correlated novel design and construction repertoires. More specifically, it focuses on implementing circular biological cycles, in which renewable plant-based resources are returned to the biosphere at the end of their life cycle. While wood is the only significant renewable building material today, truly sustainable development may be achieved with the diversification of renewable materials, to avoid dependence on a single resource. Regional and fast-regrowing plant-based materials - such as willow and poplar – have the potential to become the European local version of bamboo. In combination with alternatives to conventional aggregates - namely clay and loam – they showcase how they could achieve durable and structural building elements. Digital design and fabrication methods can address these global challenges and enable novel concepts of digital circular construction through tailored processes for renewable and natural materials.

Wicker turns digital

Wicker weaving, a technique where long thin sticks, stems or reeds are woven together to make baskets, represents an important analogy of how to exploit geometry and textile techniques to give structural stiffness not otherwise inherent in the materials. Typical of traditional manufacturing, “wicker” expresses the intention of looking back at local, renewable materials and techniques that used to be part of the architectural and construction repertoire but have been sidelined in the first industrial revolution. One of such construction methods is exemplified by the European vernacular wattle and daub, in which renewable and natural materials are combined into a low-impact sustainable composite. Digital design and fabrication methods can re-enable the industrialisation of natural materials through accommodation of deviations and abnormalities, which currently represent one of the biggest obstacles in standardised serial production systems. Thanks to their flexibility and versatility, digital production techniques enable architecture components that are designed and fabricated with a high resolution and articulation of structure and materiality but also of graded transparency and rich visual details. Finally, they can enable the large-scale, automated production of components thus facilitating their implementation in construction, both in terms of construction technology and economics.

Photo gallery

Karlsruhe Institute of Technology - Department of Architecture

Professur Digital Design and Fabrication (DDF)

Tenure-Track Prof. Moritz Dörstelmann, Erik Zanetti, Eszter Olah, Daniel Fischer

Professur Design of Structures (dos)

Prof. Dr.-Ing. Professor Riccardo La Magna, Tamara Haußer, Gianluca Casalnuovo

Students M.Sc. course “Digital Wicker 2.0”:

Teodora Bondar, Elisabeth Genest, Shunze Hou, Alicia Pizzignacco, Cesar Antonio Requejo Peña, Lara Sodomann, Kalin Yanev

With the support of:

Fanny Kranz, Javier Fuentes, Michael Kalkbrenner

Maximilian Granjon, Kevin Lang, Fatemeh Shafiee, Annalena Thessmann

Project-related publications

Zanetti, E., Olah, E., Haußer, T., Casalnuovo, G., La Magna, R. and Dörstelmann, M. (2023) ‘InterTwig—Willow and Earth Composites for Digital Circular Construction’, in M.R. Thomsen, C. Ratti, and M. Tamke (eds) Design for Rethinking Resources. Springer International Publishing (Sustainable Development Goals Series), pp. 491–511. Available at: https://doi.org/10.1007/978-3-031-36554-6_32.